Advantages of molybdenum in laser reflector

Product information:

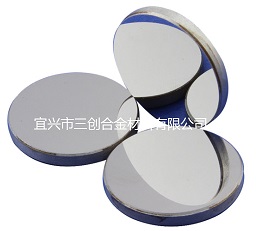

Name: molybdenum reflector

Grade: mo1

Purity: 99.6%

Specifications: Φ 20X3 Φ 25X3 Φ 30X3 3 Φ 38.1X3 Φ 50.8X5(Can be processed according to customer requirements)

Product use:Mo has the characteristics of high temperature strength, high hardness, high density, strong corrosion resistance, small thermal expansion coefficient, good conductivity and heat conduction. Molybdenum has high surface strength and excellent heat dissipation effect. It is an ideal material suitable for various harsh physical environment. The conventional molybdenum mirror is a non coated product.

Product features:

- Molybdenum mirrors are more resistant to wiping (molybdenum is silver white metal, with higher hardness, Mohr hardness of 5-5.5, atomic radius of 0.143nm, atomic volume of 235.5p * / mol, coordination number of 8. Molybdenum mirrors made of molybdenum are more resistant to wiping.)

- High temperature resistance and corrosion resistance. Molybdenum has a high melting point, ranking sixth among the natural elements. Molybdenum is called refractory metal, and its melting point is as high as 2622 ℃. Therefore, it is highly resistant to high temperature and corrosion, and is very suitable to be used as a high-density energy mirror of laser;

- High reflectivity and stable performance (molybdenum reflector does not need coating, and the reflectivity at the wavelength of 10.6um can reach more than 95%. It is extremely difficult for molybdenum to lose seven or eight electrons, which determines that the chemical substance of molybdenum is very stable);

- High strength and longer service life (molybdenum has high surface strength, high hot spot, stable chemical properties, and is suitable for working in very harsh environment, so its service life is longer)

logo.png)